The Hazardous Energy Control Program describes the Company's procedures for protecting employees from the hazards of unexpected energization, start up, or release of stored energy during maintenance and servicing of machinery and equipment. It is a goal of the Company and is mandatory under OSHA regulations to comply with the procedures detailed in this program in order to help prevent injuries and fatalities while maintenance or service is performed on equipment or machinery in the workplace.

This program applies to all management, employees, visitors and contractors at the Company’s location, where the de-energization of equipment is required to prevent the unexpected startup of machinery and other equipment, and where control of hazardous energy measures will be used.

Implementation Steps in this Guide

-

Review, Edit and Distribute the Hazardous Energy Control Policy

-

Edit and Assign the Hazardous Energy Control: Class I Procedure Guideline

-

Edit and Assign the Hazardous Energy Control: Class II Procedure Guideline

-

Edit and Assign the Hazardous Energy Control: Energy Source Audit Guideline

-

Edit and Assign the Hazardous Energy Control: General Procedure Guideline

-

Schedule the Lockout/Tagout: Authorized Employee (Spanish) Training

-

Schedule the NFPA 70E Electrical Safety in the Workplace Training

-

Schedule the Hazardous Energy Control Program Audit/Review Checklist Form

Review, Edit and Distribute the Hazardous Energy Control Policy

Review and edit the policy

- Click on the Library tab

- Search for "Hazardous Energy Control Policy" and click on it

- Click on the Edit button to view the list of versions

- Click Create Draft to the right of the latest published version

- Click Edit next to the Draft version that you just created

- Make desired changes to the policy

- Click Publish to finish editing the policy

- Click on the Permissions subtab

- Add the appropriate group(s) of users who have permission to view this policy within the library

- Click Submit to save

Schedule the activity for distribution

- Click on the Workspaces tab

- Click on the Safety workspace

- Click on the Hazardous Energy Control initiative

- Click on the Hazardous Energy Control Policy

- Click on Groups and assign to the appropriate groups, such as all management, employees, visitors and contractors at the Company’s location, where the de-energization of equipment is required to prevent the unexpected startup of machinery and other equipment, and where control of hazardous energy measures will be used.

- Click on Schedule and set an annual schedule based on the Hire Date.

- Click Save

Edit and Assign the Hazardous Energy Control Guideline

- Click on the Library tab

- Search for "Hazardous Energy Control Guideline" and click on it

- Click on the Edit button to view the list of versions

- Click Create Draft to the right of the latest published version

- Click Edit next to the Draft version that you just created

- Make desired changes to the guideline

- Click Publish to finish editing the guideline

- Click Permissions and assign to the appropriate group(s), such as all management, employees, visitors and contractors at the Company’s location, where the de-energization of equipment is required to prevent the unexpected startup of machinery and other equipment, and where control of hazardous energy measures will be used.

Edit and Assign the Hazardous Energy Control: Class I Procedure Guideline

- Click on the Library tab

- Search for "Hazardous Energy Control: Class I Procedure Guideline" and click on it

- Click on the Edit button to view the list of versions

- Click Create Draft to the right of the latest published version

- Click Edit next to the Draft version that you just created

- Make desired changes to the guideline

- Click Publish to finish editing the guideline

- Click Permissions and assign to the appropriate group(s), such as all management, employees, visitors and contractors at the Company’s location, where the de-energization of equipment is required to prevent the unexpected startup of machinery and other equipment, and where control of hazardous energy measures will be used.

Edit and Assign the Hazardous Energy Control: Class II Procedure Guideline

- Click on the Library tab

- Search for "Hazardous Energy Control: Class II Procedure Guideline" and click on it

- Click on the Edit button to view the list of versions

- Click Create Draft to the right of the latest published version

- Click Edit next to the Draft version that you just created

- Make desired changes to the guideline

- Click Publish to finish editing the guideline

- Click Permissions and assign to the appropriate group(s), such as all management, employees, visitors and contractors at the Company’s location, where the de-energization of equipment is required to prevent the unexpected startup of machinery and other equipment, and where control of hazardous energy measures will be used.

Edit and Assign the Hazardous Energy Control: Energy Source Audit Guideline

- Click on the Library tab

- Search for "Hazardous Energy Control: Energy Source Audit Guideline" and click on it

- Click on the Edit button to view the list of versions

- Click Create Draft to the right of the latest published version

- Click Edit next to the Draft version that you just created

- Make desired changes to the guideline

- Click Publish to finish editing the guideline

- Click Permissions and assign to the appropriate group(s), such as person involved in an Energy Source Audit

Edit and Assign the Hazardous Energy Control: General Procedure Guideline

- Click on the Library tab

- Search for "Hazardous Energy Control: General Procedure Guideline" and click on it

- Click on the Edit button to view the list of versions

- Click Create Draft to the right of the latest published version

- Click Edit next to the Draft version that you just created

- Make desired changes to the guideline

- Click Publish to finish editing the guideline

- Click Permissions and assign to the appropriate group(s), such as all management, employees, visitors and contractors at the Company’s location, where the de-energization of equipment is required to prevent the unexpected startup of machinery and other equipment, and where control of hazardous energy measures will be used.

Schedule the Lockout / Tagout Training

| Title | Duration (Minutes) | Type | Description |

| Lockout / Tagout Training | 36 | Course |

The OSHA standard for The Control of Hazardous Energy (Lockout/Tagout), outlines workplace safety procedures to ensure that dangerous machines are properly shut off and not able to be restarted prior to the completion of maintenance or servicing. This requires isolating hazardous energy sources by powering down machines and equipment to render them inoperative. In this course, you will gain understanding of the following concepts: |

- Click on the Workspaces tab

- Click on the Safety workspace

- Click on the Hazardous Energy Control initiative

- Click on the Lockout / Tagout Training

- Click on Groups and assign the appropriate groups, such as all management, employees, visitors and contractors at the Company’s location, where the de-energization of equipment is required to prevent the unexpected startup of machinery and other equipment, and where control of hazardous energy measures will be used.

- Click on Schedule and assign an annual schedule based on the employee's hire date

- Click Save

Schedule the Lockout/Tagout: Affected Employee Training

| Title | Duration (Minutes) | Type | Description |

| Lockout/Tagout: Affected Employee Training | 21 | Course |

This course provides information about control of hazardous energy and work under the protection of a lockout/tagout permit. The intent of the course is to provide information on lockout/tagout practices and the significance of lockout/tagout devices. The content in this course is designed to comply with the intent of the applicable regulatory requirements. Learner objectives are to define terms commonly used in a lockout/tagout program, describe specific lockout/tagout techniques commonly used in a lockout/tagout program, and recall standard lockout/tagout procedures. This course was developed with subject matter support provided by EnSafe Inc., a global professional services company focusing on engineering, environment, health and safety, and information technology.

|

- Click on the Workspaces tab

- Click on the Safety workspace

- Click on the Hazardous Energy Control initiative

- Click on the Lockout/Tagout: Affected Employee Training

- Click on Groups and assign the appropriate groups, such as all management, employees, visitors and contractors at the Company’s location, where the de-energization of equipment is required to prevent the unexpected startup of machinery and other equipment, and where control of hazardous energy measures will be used.

- Click on Schedule and assign an annual schedule based on the employee's hire date

- Click Save

Schedule the Lockout/Tagout: Authorized Employee Training

| Title | Duration (Minutes) | Type | Description |

| Lockout/Tagout: Authorized Employee Training |

69 | Course |

This course provides information about control of hazardous energy and work under the protection of a Lockout/Tagout permit. The intent of the course is to provide information on lockout and tagout practices and the significance of lockout and tagout devices. |

- Click on the Workspaces tab

- Click on the Safety workspace

- Click on the Hazardous Energy Control initiative

- Click on the Lockout/Tagout: Authorized Employee Training

- Click on Groups and assign the appropriate groups, such as all management, employees, visitors and contractors who are authorized to lockout and/or tagout energized equipment

- Click on Schedule and assign an annual schedule based on the employee's hire date

- Click Save

Schedule the Lockout/Tagout: Authorized Employee (Spanish) Training

| Title | Duration (Minutes) | Type | Description |

| Lockout/Tagout: Authorized Employee (Spanish) Training | 30 | Course |

Este curso proporciona información sobre el control de energía peligrosa y trabajo con la protección de un permiso de bloqueo/etiquetado. La intención de este curso es proporcionar información sobre las prácticas de bloqueo/etiquetado y el significado de los dispositivos correspondientes. El contenido de este curso está diseñado para cumplir con el objetivo de los requisitos normativos aplicables. Los objetivos de aprendizaje son describir los términos frecuentes en un programa de bloqueo/etiquetado, describir las técnicas específicas de bloqueo/etiquetado utilizadas en un programa de bloqueo/etiquetado y repasar los procedimientos estándar de bloqueo/etiquetado. Este curso se desarrolló con el apoyo de temas proporcionados por EnSafe Inc., una compañía de servicios profesionales mundial que se enfoca en ingeniería, medioambiente, salud y seguridad y tecnología de la información. |

- Click on the Workspaces tab

- Click on the Safety workspace

- Click on the Hazardous Energy Control initiative

- Click on the Lockout/Tagout: Authorized Employee (Spanish) Training

- Click on Groups and assign the appropriate groups, such as all Spanish speaking management, employees, visitors and contractors at the Company’s location, where the de-energization of equipment is required to prevent the unexpected startup of machinery and other equipment, and where control of hazardous energy measures will be used.

- Click on Schedule and assign an annual schedule based on the employee's hire date

- Click Save

Schedule the NFPA 70E Electrical Safety in the Workplace Training

| Title | Duration (Minutes) | Type | Description |

| NFPA 70E Electrical Safety in the Workplace Training | 120 | Course |

This course provides a comprehensive overview of the basic criteria for electrical safety-related work practices stipulated in the National Fire Protection Agency (NFPA) 70E Standard for Electrical Safety in the Workplace. It presents detailed information on the practices, programs, techniques, and processes related to electrical work, in accordance with the NFPA Standard. This course was developed with subject matter support provided by EnSafe Inc., a global professional services company focusing on engineering, environment, health and safety, and information technology. |

- Click on the Workspaces tab

- Click on the Safety workspace

- Click on the Hazardous Energy Control initiative

- Click on the NFPA 70E Electrical Safety in the Workplace Training

- Click on Groups and assign the appropriate groups, such as all management, employees, visitors and contractors at the Company’s location, where the de-energization of equipment is required to prevent the unexpected startup of machinery and other equipment, and where control of hazardous energy measures will be used.

- Click on Schedule and assign an annual schedule based on the employee's hire date

- Click Save

Schedule the Hazardous Energy Control Program Audit/Review Checklist Form

Use this form to audit your organization's Hazardous Energy Control Program.

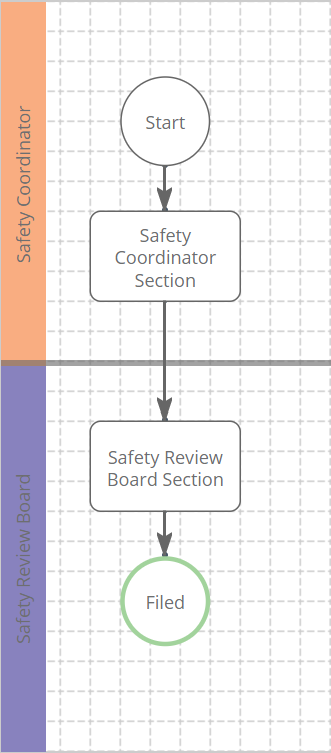

Review the Process Workflow

Set the form routing

- Click on the Admin tab

- Click on Workflow/Forms subtab

- Click on Processes

- Search for and click on Hazardous Energy Control Program Audit/Review Checklist Form

- Edit the routing rules for each stage by following these suggestions:

Stage Suggested Routing Rule Description Safety Coordinator Section Subject or Queue Route to the "Subject" (i.e. the person to whom the system sent this form). This stage can alternatively be assigned to a queue. Safety Review Board section Queue Route to the Compliance Officer, Safety Review Board or Senior Management Queue, or equivalent.

Schedule the Activity for distribution

- Click on the Workspaces tab

- Click on the Safety workspace

- Click on the Hazardous Energy Control initiative

- Click on the Hazardous Energy Control Program Audit/Review Checklist Form

- Click on Groups and assign to the appropriate group(s), such as your Safety Coordinator

- Click on Schedule and set the appropriate schedule. We suggest at least an annual schedule. Be sure to add a number of days to distribute the form before it is due.

- Click Save

Comments

0 comments

Please sign in to leave a comment.